Moulded (curved) glass of JSC “RGC" is produced by the newest equipment, providing bending of large format glass. Vast engineering capabilities of the company allow producing curved triplex, curved insulating glass units, with the application of any graphic image that provides unlimited possibilities of application in facade and interior glazing. Any architectural solutions are feasible with the capabilities of the Russian Glass Company.

Curved glass - polished glass heated up to a softening temperature and bent by using metal mould according to the given radius.

All the glass, which has passed the moulding process in JSC “RGC" is tempered and is considered to be a safety glass.

Application:

-

Bent double glazing for windows

-

Glazing of facades

-

Facing loggias, balconies

-

Roof glazing

-

Atria

-

Rooflights

-

Storefronts

-

Interior glazing

-

Partition

-

Shower cabins

-

Glass furniture

-

Glazing of lifts and escalators

-

Stair fencing

Single curved glass

Single curved glass

Curved glass with application with enamel

Curved glass with application with enamel

Curved glass with digital printing

Curved glass with digital printing

Curved glass with screen printing

Curved glass with screen printing

Laminated curved tempered glass

Laminated curved tempered glass

Laminated curved glass with enamel

Laminated curved glass with enamel

Laminated curved silk-screen printed glass

Laminated curved silk-screen printed glass

Laminated curved glass with digital printing

Laminated curved glass with digital printing

Curved tempered insulating glass unit

Curved tempered insulating glass unit

Curved insulating glass unit with enamel

Curved insulating glass unit with enamel

Curved insulating glass unit with silk-screen printed

Curved insulating glass unit with silk-screen printed

Curved insulating glass unit with digital printing

Curved insulating glass unit with digital printing

|

type of glass |

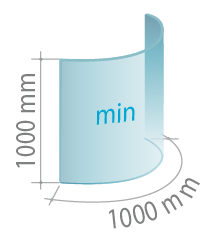

minimum size |

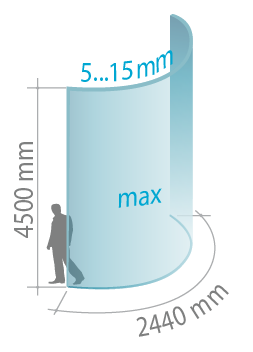

maximum size |

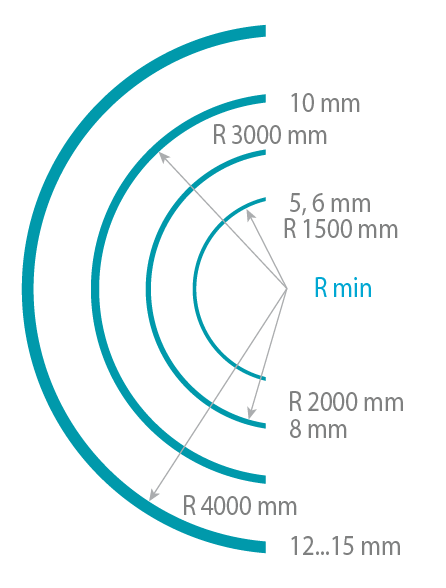

minimum bending radius |

|---|---|---|---|

|

polished glass low-emissivity glass sun-protective glass multifunctional glass |

1000 х 1000 mm |

2440 х 4500 mm |

|

Production technology:

The glass is gradually heated to a temperature of 600ºC in a special furnace. In a softened state, the glass under action of gravity is formed around the concave die, located horizontally inside the furnace and it takes a predetermined geometrical shape and bending radius. When the moulding process is completed, the curved glass is cooled by cold air under pressure. As a result, the curved glass is tempered and gains strength.

Order recommendations

When ordering one should submit three groups of information

1. Product description (type of glass (trademark), glass thickness, type of edging)

For a curved laminated glass one should describe the type of glass, the orientation of the coating (if any) thickness of each glass and in- between glass layers of PVB film.

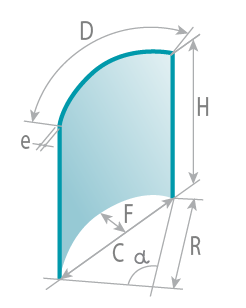

2. The height of the cylinder (H) generating line

3. The curve is defined by 2 of the following parameters:

D = effective length; C = chord length; F = deflection; R = radius of curvature; α = central angle.

Preferably, the arc length point along the concave plane and the radius of curvature. By default, all the parameters are calculated always from the inside (concave surface). For complicated products the customer must provide the workpiece drawing with cutouts, holes in the overall dimensions of the inner arc length.

When bending glass with a magnetron sputtering, the deposition is on the concave side of the article. When bending emalita enamel will be on the concave side of the product.

1. Incoming inspection of materials and components

2. The curved tempered glass of JSC “RGC" production is manufactured in accordance with STO 94610236-004 “Safety glass tempered”

3. Tempered glass of JSC “RGC" production is manufactured in accordance with GOST R 54162-2010, which is confirmed by certificates of compliance and test protocols for manufactured products.

4. The tempered glass produced by the JSC “RGC" complies with the international standards EN -12150:2000, EN 14179:2001, DIN 1249.

5. The possibility of conducting a Heat Soak Test in order to reduce significantly the probability of spontaneous destruction of the tempered glass.

-

Manufacturing of curved tempered glass in large format

-

The possibility of moulding low-emissivity coated glass

-

High optical and mechanical characteristics, conforming to GOSTs, european and world standards