Manufacturing of a tempered safety glass is one of the priorities of the Russian Glass Company. Increasing the strength of glass 5 times, maintaining large temperature differences, safety when broken - these advantages of the tempered glass are widely used in architectural glazing facilities, in housing and vehicle glazing

Tempered glass is 4-5 times stronger than non- tempered one, used as a source material. Tempering of the glass is one of the ways to increase glass strength by changing its characteristics. Thermally tempered glass is considered safe, as in the case of the glass fracture its splinters are not sharp and far smaller than that of a simple glass, which limits the risk of cuts.

Functions:

-

Protection of people against injury by broken glass

-

Protection against burglary and vandalism

-

Protection against firearms, explosions (* in the composition of laminated glass)

-

Resistance to thermal breakage

The main area of application of the tempered glass is interior and facade glazing with increased requirements for physical security of people and also in the cases when the increased resistance to thermal stress is necessary.

Single-pane glazing

Single-pane glazing

In the composition of laminated glass

In the composition of laminated glass

In the composition of the insulating glass unit

In the composition of the insulating glass unit

Moulded (curved) tempered glass

Moulded (curved) tempered glass

Moulded (curved) tempered glass in the composition of laminated glass

Moulded (curved) tempered glass in the composition of laminated glass

Moulded (curved) tempered glass in the composition of the insulating glass unit

Moulded (curved) tempered glass in the composition of the insulating glass unit

|

Type of glass |

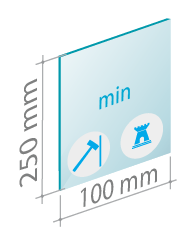

Minimum size |

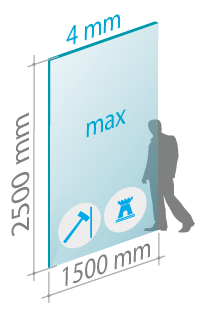

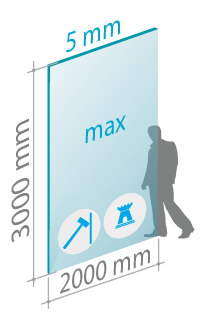

Maximum size |

|---|---|---|

|

polished glass low-emissivity glass sun-protective glass multifunctional glass |

100 х 250 mm |

4 mm - 1500 х 2500 mm |

|

5 mm - 2000 х 3000 mm |

||

|

6….19 mm - 3210 х 6000 mm |

All kinds of float glass, tinted glass, glass with solid pyrolysis-induced coatings, and some types of glass with a magnetron coating can be subjected to tempering:

AGC production - TopN+T, Energy NT, StoprayT.

Guardian production - HT-Version, SunGuard Solar, SunGuard High Performance.

Pilkington production - Pro-T, Optitherm, Suncool.

* For more information, consult our experts.

Production technology:

Thermally tempered glass - glass is subjected to special heat treatment; it is heated to approximately 600 ° C, then rapidly cooled by air jets. On the surface of the glass there is a body-stressed state. This makes it more resistant to mechanical and thermal loads and gives the required parameters in the destruction of fragmentation. Tempered glass is not possible for a subsequent treatment, so there is tempered not a sheet glass but the product after being sliced to the required size and processed. Production facilities of JSC "RGC" are equipped with the modern tempering furnaces Tamglass, providing tempering of complicated coated glass also in jumbo-format.

1. Incoming inspection of materials and components

2. Tempered glass of JSC “RGC" production is manufactured in accordance with GOST 33087-2014, which is confirmed by certificates of compliance and test protocols for manufactured products.

In accordance with GOST the tempered glass passes through the following types of tests:

-

Test of mechanical strength

-

Test on the nature of destruction

-

Testing the optical characteristics

3. The tempered glass produced by the JSC “RGC" complies with the international standards EN -12150:2000, EN 14179:2001, DIN 1249.

4. Tempered glass of JSC “RGC" production is manufactured in accordance with STO 94610236-004 dated 2014. “Safety glass tempered”

5. Quality management system compliance to international standard ISO 9001:2008

6. The possibility of conducting a Heat Soak Test in order to significantly reduce a probability of spontaneous tempered glass destruction.

-

Manufacturing of Jumbo-format tempered glass

-

The possibility of tempering low-emissivity coated glass

-

High optical and mechanical characteristics, conforming to GOSTs, European and world standards