Silk-screen printing is widely used for mechanical engineering - glazing of railway transport and special-purpose equipment, as well as in the construction industry - facade glazing, glass for interior decorating use.

Silk-screen printing is a technology of applying mainly monochrome images on sheet glass. Applying images on the glass surface is carried out through the screen-printing (matrix). Ceramic baked paints are used for the silk-screen printing.

Functions:

-

the possibility of decorating the glass elements in the facade and interior glazing

-

additional possibility of limiting the excessive solar radiation

Glass with silkscreen printing (*always tempered/heat-strengthened)

Glass with silkscreen printing (*always tempered/heat-strengthened)

Moulded (curved) silk-screen printed glass

Moulded (curved) silk-screen printed glass

laminated glass with silkscreen printing

laminated glass with silkscreen printing

Moulded (curved) laminated glass with silk-screen printing

Moulded (curved) laminated glass with silk-screen printing

Insulating glass unit with silk-screen printing

Insulating glass unit with silk-screen printing

Moulded (curved) insulating glass unit with silk-screen printing

Moulded (curved) insulating glass unit with silk-screen printing

|

type of glass |

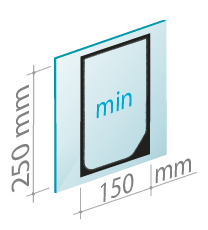

minimum size of the picture |

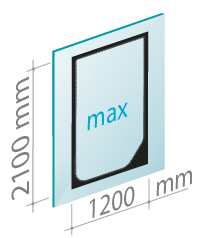

maximum size of the picture |

|---|---|---|

|

polished glass tinted glass with pyrolytically coated glass solid |

150 х 250 mm |

1200 х 2100 mm |

Production technology:

Using a stencil with applied pattern on it the enamel is applied on the glass. Glass with printed pattern is subjected to the thermal treatment (tempering / thermo strengthening), as a result of which the figure is baked into the glass surface and becomes part of it.

1. Incoming inspection of materials and components

2. Glass with the screen printing production of JSC “RGC" is always tempered, so it is manufactured in accordance with GOST R 54162-2010, which is confirmed by Certificates of compliance and test protocols for manufactured products.

3. Complies with the international standards EN 12150-1, EN 1863-1, EN 14179:2001.

4. The screen-printing production of JSC “RGC" is manufactured in accordance with STO 94610236-002-2013.

5. Quality management system compliance to international standard ISO 9001:2008

6. The possibility of conducting a Heat Soak Test with the aim of significantly reducing the probability of spontaneous destruction of the tempered glass.

-

High strength to mechanical and thermal influences

-

Durability in various climate conditions

-

Resistance to scratching and abrasion

-

Economy with significant prints