Laminated Glass is widely used in architectural, residential and transportation glazing due to its unsurpassed characteristics for safety, soundproof properties, as well as wide selection of colour palette. Today JSC “RGC" offers its customers the widest range of the products from laminated glass with all types of glass (including coated, mass- coloured) of different protection class, with the possibility of selection of the necessary shade on the RAL scale with application of the silk screen printing or digital image.

Laminated Glass - glass consisting of two or more glass sheets and one or more intermediate layers of PVB-film (PVB) (polyvinyl butyral) or EVA (ethylene-vinyl acetate).

PVB films are produced as colourless, opaque or painted on RAL scale, as well as anti-noise.

EVA films are used for manufacturing of decorative laminated glass when the glass is laid between the film and different materials: textured fabric, photos, composition of the wood elements, leaves of plants, metal, etc.

Laminated glass composition and number of intermediate layers define the protection level of the laminated glass for providing safety of people and property, protection against theft, armed assaults and explosions. Multilayer laminated glass (triplex) is an excellent design element for safety glazing.

Functions:

-

To prevent the risk of cuts and injuries in case of accidental breakage of glass - composition must comply with the protection class for safety during operation (CM1-CM4 - in accordance with GOST R 54171-2010);

-

Protection of people against falling through the glass in case of its destruction - composition must comply with the protection class for resistance to impact (R1A-R5A - in accordance with GOST R 54171-2010);

-

Property protection against intruders breaking and entering, vandalism and theft - composition must comply with the protection class burglar (R6V-R8V in accordance with GOST R 54171-2010);

-

Protection against armed attack - composition must comply with the protection class bulletproof (P1-P6a - in accordance with GOST R 54171-2010);

-

Protection against terrorist acts - composition must comply with the protection class for explosion resistance (SB1 SB7 (X) (X), EXV45 (X) EXV10 (X) - in accordance with GOST R 54171-2010).

Laminated glass with application of screen-printing

Laminated glass with application of screen-printing

Laminated glass with digital printing

Laminated glass with digital printing

Enamelled laminated glass

Enamelled laminated glass

Figures from the laminated glass

Figures from the laminated glass

Moulded (curved) laminated glass

Moulded (curved) laminated glass

Moulded (curved) laminated glass with enamel

Moulded (curved) laminated glass with enamel

Moulded (curved) laminated glass with digital printing

Moulded (curved) laminated glass with digital printing

Laminated glass as composed of insulating glass unit

Laminated glass as composed of insulating glass unit

Production capacities of JSC “RGC" allow producing non-standard laminated glass: from special glass with coatings, with tempered coated and heat-strengthened glass, with enamel, with digital image.

|

type of glass |

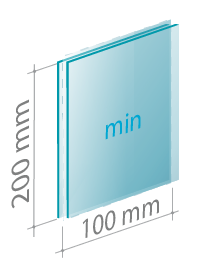

Minimum size |

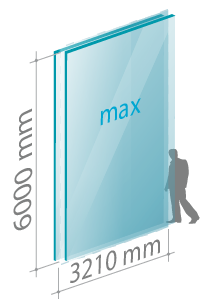

Maximum size |

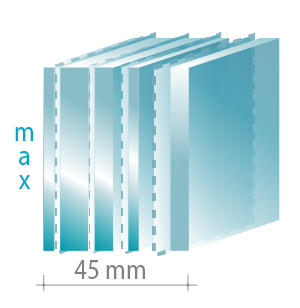

Maximum thickness |

|---|---|---|---|

|

polished glass low-emissivity glass sun-protective glass multifunctional glass tempered glass heat-strengthened glass Moulded (curved) glass |

100 х 200 mm |

3210 х 6000 mm |

45 mm |

Technology:

Washed glass is loaded onto the glass laminating line and sent to the "clean" room. A polyvinyl butyral (PVB) film is laid between the glass sheets in the “clean” room after which the package receives preliminary pre-moulding in the colander for conducting preliminary gluing of the assembled triplex. In the colander the triplex is warmed up to the temperature of 110-115°C and the air between the layers of glass and film is mechanically extruded using the rubber rollers, that leads to a certain film adhesion to the glass. Final pressing occurs in an autoclave with a temperature of +150°C and pressure of 12.5 B

1. Laminated glass of JSC “RGC" production is manufactured in accordance with the existing regulations - GOST R 54171-2000, GOST R 51136-2008, which is confirmed by certificates of compliance and test protocols for manufactured products.

2. In accordance with GOST R 54171-2000 the laminated glass of JSC “RGC" production pass the following tests:

-

Falling ball test for a strength class to determine the protection class of an impact resistant glass

-

Soft body test to determine laminated glass protection class

-

Testing adhesive materials to determine the boiling temperature resistance

3.Permanent independent control of the production by the regional independent certification bodies in the construction: “Sevzapstrojsertifikaciya" and "Center of construction quality”.

4. Compliance with the Quality Management System ISO 9001:2008

5. Ability to conduct any further tests and customer-requested tests

-

Possibility to manufacture laminated glass of any protection class and size

-

Manufacturing of all glass types, including the coated one, with tempered and heat- strengthened glasses.

-

Decorative laminated glass with digital and screen printing

-

Special sound-proof laminated glass