In compliance with the Federal Law of the Russian Federation No. 123-FZ "Technical Regulations on Fire Safety Requirements", translucent structures shall comply with fire resistance requirements.

Ordinary polished glass, laminated glass (triplex), double glazed units do not withstand thermal shock during a rapid rise in temperature during a fire and burst within 8-10 minutes.

To protect against fire, smoke and combustion products, there are 2 types of fire-resistant glass:

● Monolithic fire-resistant glass

● Laminated fire-resistant glass

Monolithic fire-resistant glass is a monolithic specially tempered glass that meets the integrity criteria for fire resistance classes from E15 to E60 (as part of an insulated glass unit). Due to exposure to high temperatures on such glass, it does not become cloudy and does not expand, retains its integrity for the time specified in the formula (in minutes).

Laminated fire-resistant glass is laminated glass with transparent, heat-expanding intermediate layers. In the event of a fire at a temperature of about 120°C, these layers change their physical properties and the glass turns into a rigid and opaque protective structure, allowing the glazing to maintain:

-

● integrity, i.e. to ensure the absence of through cracks or holes through which combustion products or flames penetrate;

● thermal insulation capacity, i.e. to prevent the transfer of heat to the protected space by means of radiation.

Based on the capacity to maintain integrity, limit or completely prevent thermal radiation (transfer of thermal energy), fire-resistant glass is divided into 3 classes of fire resistance (fire rating):

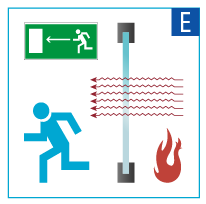

Fire Rating Class E –glass retains its integrity, prevents the penetration of flame, smoke and hot gases (but not thermal radiation) for a certain time without the formation of through cracks or holes.

Fire Rating Class E –glass retains its integrity, prevents the penetration of flame, smoke and hot gases (but not thermal radiation) for a certain time without the formation of through cracks or holes.

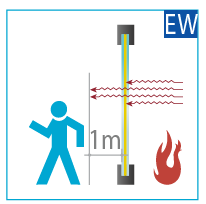

Fire Rating Class EW – structure retains its integrity and limits thermal radiation (heat transfer) to the protected space.

Fire Rating Class EW – structure retains its integrity and limits thermal radiation (heat transfer) to the protected space.

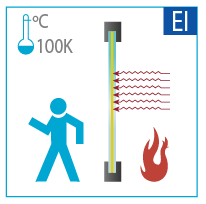

Fire Rating Class EI - structure retains its integrity and completely prevents the penetration of thermal radiation (heat transfer) to the protected space. The glass temperature on the side opposite to the fire is not more than 140°C (average) or 180°C (at one measurement point) higher than the glass temperature under normal conditions.

Fire Rating Class EI - structure retains its integrity and completely prevents the penetration of thermal radiation (heat transfer) to the protected space. The glass temperature on the side opposite to the fire is not more than 140°C (average) or 180°C (at one measurement point) higher than the glass temperature under normal conditions.

The fire rating of each element is determined by the time (in minutes) during which this element can satisfy all the evaluation criteria: at least 15 - 30 - 45 - 60 - 90 - 120 - 180 minutes.

Examples of Fire Rating Designation:

Facade E 30 - the structure maintains integrity for 30 minutes.

Partition EIW 45 - the structure maintains integrity and prevents the penetration of thermal radiation for 45 minutes.

Functions:

- Provision of human safety

- Protection of building infrastructure and limitation of fire damage

- Provision of safe evacuation and access for rescue and fire-fighting services

Unlike other fire-resistant materials, fire-resistant glazing provides natural light and comfortable living conditions, and also allows you to implement a variety of design solutions.

Application:

Fire-resistant glazing shall be used in cases where building codes require a certain fire rating and where natural light and visibility are important: hospitals, schools, hotels and restaurants, shops, shopping malls, office buildings, industrial buildings, warehouses, airports.

Standard Use of Fire-Resistant Glass:

- Partial or full use in fire doors

- Glazing of partitions along escape passages, division of premises into compartments

- Roof and floor glazing

- Glazing of facades, zenith skylights and atriums

- In windows to prevent the propagation of fire up and along the facade, as well as its transfer from one building to another

Single fire-resistant glazing

Single fire-resistant glazing

Fire-resistant glass of various shapes

Fire-resistant glass of various shapes

Insulated glass units made of fire-resistant glass (including combinations with coated glass)

Insulated glass units made of fire-resistant glass (including combinations with coated glass)

Glasses used:

The range of JSC RGC includes glass by sizes and insulated glass units made of fire-resistant glass produced by AGC and Pilkington

|

Producer/ Glass brand |

Type of glass |

Class E |

Class EW |

Class EIW |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Time in minutes |

30 |

60 |

30 |

60 |

15 |

30 |

45 |

60 |

90 |

120 |

180 |

|

|

AGC Pyropane |

temp. |

+ |

+ |

|

|

|

|

|

|

|

|

|

|

AGC Pyrobelite |

laminated |

+ |

+ |

+ |

+ |

+ |

|

|

|

|

|

|

|

AGC Pyrobel |

laminated |

+ | + | + | + | + | + | + | + | + | + | |

|

Pilkington Pyroclear |

temp. |

+ |

+ |

+ |

|

|

|

|

|

|

|

|

|

Pilkington Pyrodur |

laminated |

+ |

+ |

+ |

+ |

+ |

|

|

|

|

|

|

|

Pilkington Pyrostop |

laminated | + | + | + | + | + | + | + | + | + | + | + |

|

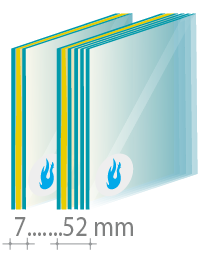

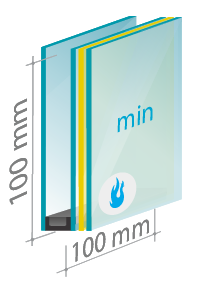

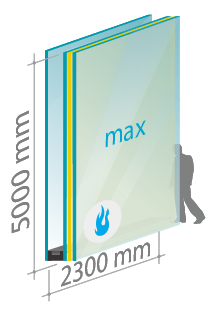

Glass Thicknes |

Min. Size |

Max. Size |

|---|---|---|

|

7 - 52 mm |

100 х 100 mm |

2000 х 3000 mm |

RGC has all the process capabilities for processing fire-resistant glass:

-

● Cutting as per the required dimensions;

● Production of various shapes (rectangle, figure, radius shape);

● Production of insulated glass units in combination with other types of glass, with any type of distance frame (including warm edge), with decorative layout, with polysulfide or silicone sealants.

Instructions when ordering tempered fire-resistant glass:

Similar to recommendations for tempered glass and insulated glass units with tempered glass

Instruction when working with multilayer fire-resistant glass:

- Do not allow any contact of glass edges with water

- Avoid contact between glass and metal;

- Always leave space for glass movement in the structure (0.5-1 mm);

- Do not damage the glass edge and protective tape;

- Use mounting units made of hard wood (Shore A 75 hardness);

- Maintain an angular clearance of 4-5 mm;

- Maintain a side clearance of 4-5 mm;

- The depth of the grooves shall be at least 20 mm;

- Keep grooves dry and free of aggressive materials (acids, organic solvents);

- Do not allow any contact of glass edges with water;

- Immediately after glazing the opening, apply a neutral silicone sealant or dry sealant.

- The glass shall not be exposed to temperatures below -40°C and above 40°C for a long time and shall not be located near heat sources. Solar protective glass may be used to prevent heating during glazing;

- Do not allow moisture to enter the glass edges. Glass shall be installed in ventilated frames with a water collection system to prevent moisture from entering the grooves;

- Do not damage or remove the protective tape.

- For facades it is necessary to use fire-resistant glass with UV filter = PVB film 0.76mm in certain types of Pyrobel or as part of an insulated glass units with external multilayer glass of at least 33.2:

or

or

- For horizontal glazing thick glass to the outside:

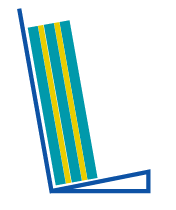

- Unpacked glass shall be stored in a vertical, slightly inclined (6-10°) position, with the obligatory support of the entire plane on the rear wall of the halt, the angle of which is 90°:

- Cases with glass or unwrapped glass shall be stored in a dry, well-ventilated area and shall be protected from sunlight.

In order to implement the declared fire-resistant qualities, fire-resistant glass shall be a part of a tested and certified structure as a whole (frame with glass) and shall be installed by specialists. An assembly or facade company that installs fire-resistant glazing shall have a license issued by the Ministry of Emergency Situations of Russia for the design, installation, repair and maintenance of fire-resistant barriers and certify its design using a specific type of glass.

Certificates are issued only by testing centers accredited by the Supervisory Department of the Ministry of Emergency Situations of Russia for the right to carry out work to confirm the conformity of products with the requirements of 123-FZ "Technical Regulations on Fire Safety Requirements".

1. JSC RGC is a licensed processor of fire-resistant glass of AGC and Pilkington

2. All types of fire-resistant glass processed by RGC have the appropriate certificates of conformity of AGC and Pilkington

3. Compliance of the quality management system with the international standard ISO 9001:2015

- AGC and Pilkington licenses for the right to process fire-resistant glass

- Large experience in the manufacture of fire-resistant translucent structures

- Ability to supply fire-resistant glass of the required shape and size

- Production of insulated glass units with both monolithic and multilayer fire-resistant glass in combination with other functional glasses (energy-saving, sun-protection, multifunctional)